ENGINEERING

POLYMERS

In the complex world of special

materials engineering,

the important role of engineering plastics

cannot be overstated.

materials engineering,

the important role of engineering plastics

cannot be overstated.

Among the types that are frequently used in this group

Polyfluoroethylene (PTFE) ,

Ultem 1000 and Polyetheretherketone (PEEK)

stand out in OPI sector application.

In exploring the

advantages of this kind of Engineering Plastics,

we embark into the remarkable realm of PTFE ,

Ultem 1000 and PEEK ,revealing their profound impact

on a wide range of industries.

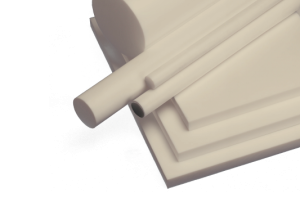

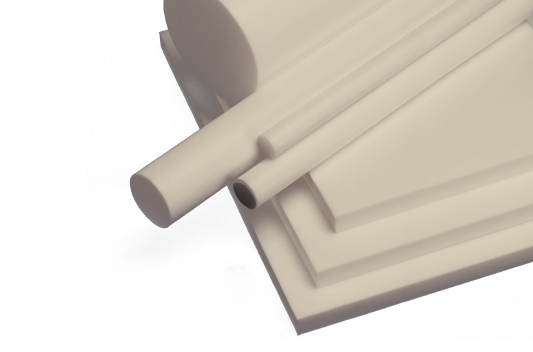

We are able to provide these kind of advance engineering plastic in various form factor :

Flat sheet, Flat bar, Round bar,

Half round Rod, D-Rod

and custom size as client requirement (by CNC machining).

PTFE Polytetrafluoroethylene

We also use PTFE ROD

in our YU-BOLT.

Advantages :

Applications

Advantages :

– Exceptional chemical resistance: PTFE is highly resistant to a wide range of chemicals, making it suitable for corrosive environments.

– Low friction: PTFE has one of the lowest coefficients of friction among solid materials, making it an excellent choice for applications

involving sliding or rotating components.

– High temperature resistance: PTFE can withstand a wide temperature range, making it suitable for use in both high and low-temperature

applications.

– Low friction: PTFE has one of the lowest coefficients of friction among solid materials, making it an excellent choice for applications

involving sliding or rotating components.

– High temperature resistance: PTFE can withstand a wide temperature range, making it suitable for use in both high and low-temperature

applications.

Applications

– Seals and gaskets: PTFE’s low friction and chemical resistance make it ideal for sealing applications in industrial settings.

– Bearings and bushings: Its low friction properties make PTFE suitable for use in bearings and bushings in various industries.

– Electrical insulation: PTFE is an excellent electrical insulator, making it suitable for use in wiring and cable applications.

– Bearings and bushings: Its low friction properties make PTFE suitable for use in bearings and bushings in various industries.

– Electrical insulation: PTFE is an excellent electrical insulator, making it suitable for use in wiring and cable applications.

Advantages :

Applications

Advantages :

– High strength and rigidity: Ultem 1000 offers excellent mechanical properties, including high strength

and rigidity.

– Dimensional stability: It maintains its shape and properties over a wide temperature range, providing

stability in different environments.

– Flame resistance: Ultem 1000 has excellent flame resistance, making it suitable for applications with stringent

fire safety requirements.

and rigidity.

– Dimensional stability: It maintains its shape and properties over a wide temperature range, providing

stability in different environments.

– Flame resistance: Ultem 1000 has excellent flame resistance, making it suitable for applications with stringent

fire safety requirements.

Applications

– Carthodic protection for pipeline

– Aerospace components: Ultem 1000 combination of high strength and flame

resistance which makes it suitable for aerospace applications.

– Medical devices: Its biocompatibility and resistance to steam sterilization make it suitable for medical device

components.

– Machine and Electrical components: Ultem 1000 is used in electrical and electronic applications due to its high   dielectric strength and dimensional stability.

– Medical devices: Its biocompatibility and resistance to steam sterilization make it suitable for medical device

components.

– Machine and Electrical components: Ultem 1000 is used in electrical and electronic applications due to its high   dielectric strength and dimensional stability.

Advantages :

Applications

Advantages :

– Very high temperature resistance: PEEK can withstand high temperatures

without significant loss of

mechanical properties.

– Chemical resistance: It is resistant to a wide range of chemicals, making it suitable for aggressive

environments.

– High mechanical strength: PEEK offers high tensile strength and stiffness, making it suitable for structural

applications.

mechanical properties.

– Chemical resistance: It is resistant to a wide range of chemicals, making it suitable for aggressive

environments.

– High mechanical strength: PEEK offers high tensile strength and stiffness, making it suitable for structural

applications.

Applications

– Carthodic protection for pipeline

– Aerospace components: Ultem 1000 combination of high strength and flame

resistance which makes it suitable for aerospace applications.

– Medical devices: Its biocompatibility and resistance to steam sterilization make it suitable for medical device

components.

– Machine and Electrical components: Ultem 1000 is used in electrical and electronic applications due to its high   dielectric strength and dimensional stability.

– Medical devices: Its biocompatibility and resistance to steam sterilization make it suitable for medical device

components.

– Machine and Electrical components: Ultem 1000 is used in electrical and electronic applications due to its high   dielectric strength and dimensional stability.

Key Features :

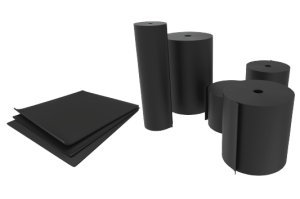

Neoprene :

Mold-Injected Neoprene :

Key Features :

In the dynamic realm of materials science, where innovation and functionalityconverge, “Neoprene”.

Renowned for its versatility and unique properties, Neoprene has found its way into an array of applications,

from protective gear to industrial components.

Moreover, the evolution leads this material into the realm of Mold-Injected Neoprene which serves modern manufacturing and material assembling system.

Renowned for its versatility and unique properties, Neoprene has found its way into an array of applications,

from protective gear to industrial components.

Moreover, the evolution leads this material into the realm of Mold-Injected Neoprene which serves modern manufacturing and material assembling system.

Neoprene :

The advantages of Neoprene which has been know for its excellent resistance to chemicals, oils,

and abrasion, Neoprene has become synonymous with durability. Its remarkable ability to maintain

flexibility across a wide temperature range, coupled with robust weather resistance, has made it

a stalwart choice in diverse industries, including marine applications, and automotive.

and abrasion, Neoprene has become synonymous with durability. Its remarkable ability to maintain

flexibility across a wide temperature range, coupled with robust weather resistance, has made it

a stalwart choice in diverse industries, including marine applications, and automotive.

Mold-Injected Neoprene :

This innovative process marries the intrinsic strengths of Neoprene with the precision of molding

techniques, resulting in a material that not only retains the original resilience of Neoprene but also

offers tailored shapes and intricate detailing.

The marriage of Neoprene’s inherent qualities with the precision of injection molding expands the

material’s applications, providing a customizable solution for industries that demand both form and

function.

techniques, resulting in a material that not only retains the original resilience of Neoprene but also

offers tailored shapes and intricate detailing.

The marriage of Neoprene’s inherent qualities with the precision of injection molding expands the

material’s applications, providing a customizable solution for industries that demand both form and

function.