YU-BOLT

about our YU-BOLT

Make A difference

The structure of crucial piping systems across various projects necessitates continuous durability and

maintenance to avert unexpected major issues. Ensuring the pipes, their surfaces, and s upporting

equipment such as pipe hangers remain well-maintained is imperative to mitigate rapid corrosion and

deterioration caused by water accumulation underneath them or the vibrating or rusty.

YU-BOLT is the solution for pipe line lifespans and eliminate failure consequences.

BOLT MATERIAL

We offer 2 bolt materials

for our YU-BOLT.

Carbon Steel

Carbon steel, in contrast to stainless steel, is an iron-carbon

alloy prized for its strength and versatility. The key characteristic

of carbon steelis its carbon content, which determines its hardness

and strength. While it may not possess the same corrosion

resistance as stainless steel, carbon steel offers exceptional

durability, making it ideal for applications where high strength

is paramount.

Commonly used in construction, manufacturing, and infrastructure,

carbon steel demonstrates cost-effectiveness and reliability,

showcasing its significance across a broad spectrum of industries.

Stainlees steel

Stainless steel stands as a robust and heat-resistant

iron-based alloy, recognized for its remarkable properties.

It boasts durability, ensuring longevity in applications

subjected to harsh conditions. Additionally, stainless-

steel maintains high hygiene standards, making it a

preferredchoice in critical environments like the medical

and food industries. Its ease of maintenance and aesthetic

qualities further enhance its appeal, making stainless-

steel a pivotal material in diverse sectors, including

construction and manufacturing.

Coating for Stainless Steel Bolt.

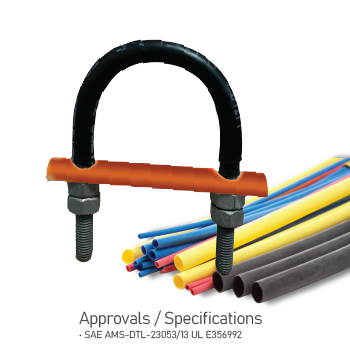

YU-BOLT INSULATOR

Polyshrink VITON

• High temperature resistant up to 200, excellent high and low temperature resistance

• Excellent abrasion resistance and resistance to oil, diesel and hydraulic fluids.

• Very flexible, highly flame-retardant

• RoHS and REACH compliant.

Operating temperature range

• Minimum shrink temperature : 150°C

• Minimum fully recovery temperature : 175°C

NEOPRENE

Neoprene rubber maintains its strength, flexing, twisting and elongation very well over a wide temperature range while having outstanding physical toughness. Marry grades of neoprene are available depending on the application.

Operating temperature range

Elongation : 200%

Tensile strength : 2.5 MPa

Hardness : 65 Shore A

Max Service Temp : 120 °c

ELASTOMER insulated TYPE Functions :

Grip / Not to Grip Neoprene

Function : Embossable & Inkjet Printable

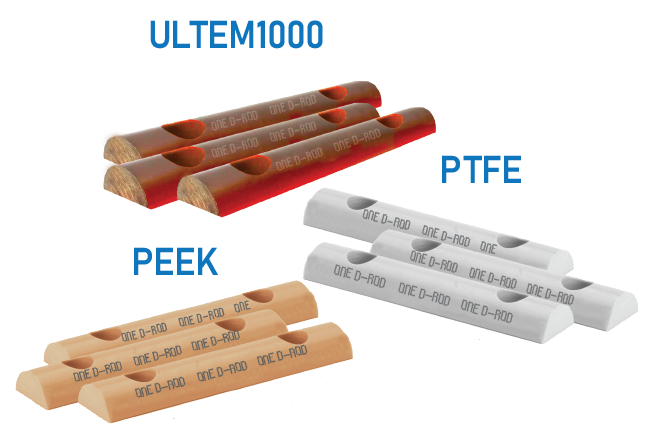

D-ROD

D-ROD is not just a support solution, but it is a shield against corrosion and a promoter of efficiency.

Crafted from robust materials like ULTEM1000 or Peek or PTFE, this design not only provides sturdy structural support but also minimizes direct contact with corrosive elements. D-ROD acts as a protective

barrier, ensuring a longer lifespan for your pipe support system.

What's more, its half-round shape

optimizes surface area, promoting efficient water

evaporation in outdoor or challenging environments.

Simple, effective, and designed with your needs in mind,

our solution prioritizes longevity, reliability

and efficiency for your pipe support requirements.

Ultem1000 stands out as a semi-transparent amorphous thermoplastic renowned for its exceptional steam and heat resistance, coupled with extraordinary dielectric properties. With a continuous service temperature of approximately 170°C, Ultem 1000 (PEI) is well-suited for applications demanding high strength and rigidity, especially in elevated temperature conditions.

PTFE is a versatile polymer renowned for its low friction coefficient, high-temperature resistance, chemical inertness, excellent electrical insulation, nonstick properties, biocompatibility, and UV resistance. This combination makes it invaluable in various applications, from reducing friction in bearings to serving as a nonstick coating in cookware. Its stability, flexibility at low temperatures, and resistanceto chemicals contribute to its widespread use across industries.

PEEK possesses outstanding mechanical strength, exceptional resistance to chemicals and hydrolysis, and is highly resilient to steam and radiation. With a continuous service temperature of approximately 250º C, it is well-suited for applications in elevated temperatures, maintaining its physical properties unaffected by external factors thanks to its excellent thermal characteristics.

![]()

![]()

Selection Guides

DURABILITY & RELIABILITY WITH FULLY INSULATED U-BOLT

We have got several materials for YU-BOLT, D-ROD,

(Thermal Plastic Insulator), YU-Pad and YU-BOLT shank

insulator to suit for specific job and for maximum

protection efficiency.