FASTENER

OPI is a stockiest and partner of leading manufacturer and distributor of Bolts and Nuts worldwide.

We offer a wide-range of regular and custom-made fasteners made to internationally-upheld safety

and quality standards for various project worldwide.

Our partners ramains at the forefront in implementing new safety standards and technology by

continually upgrading themselves and investing heavily in state – of – the – art machinery that deliver

fasteners of the highest quality.

We also take pride in delivering excellent customer service through prompt response and willingness

to our clients, operations and challenges. Our experiences are able to assist our client for cost- efficient,

on-time delivery through anywhere in the world.

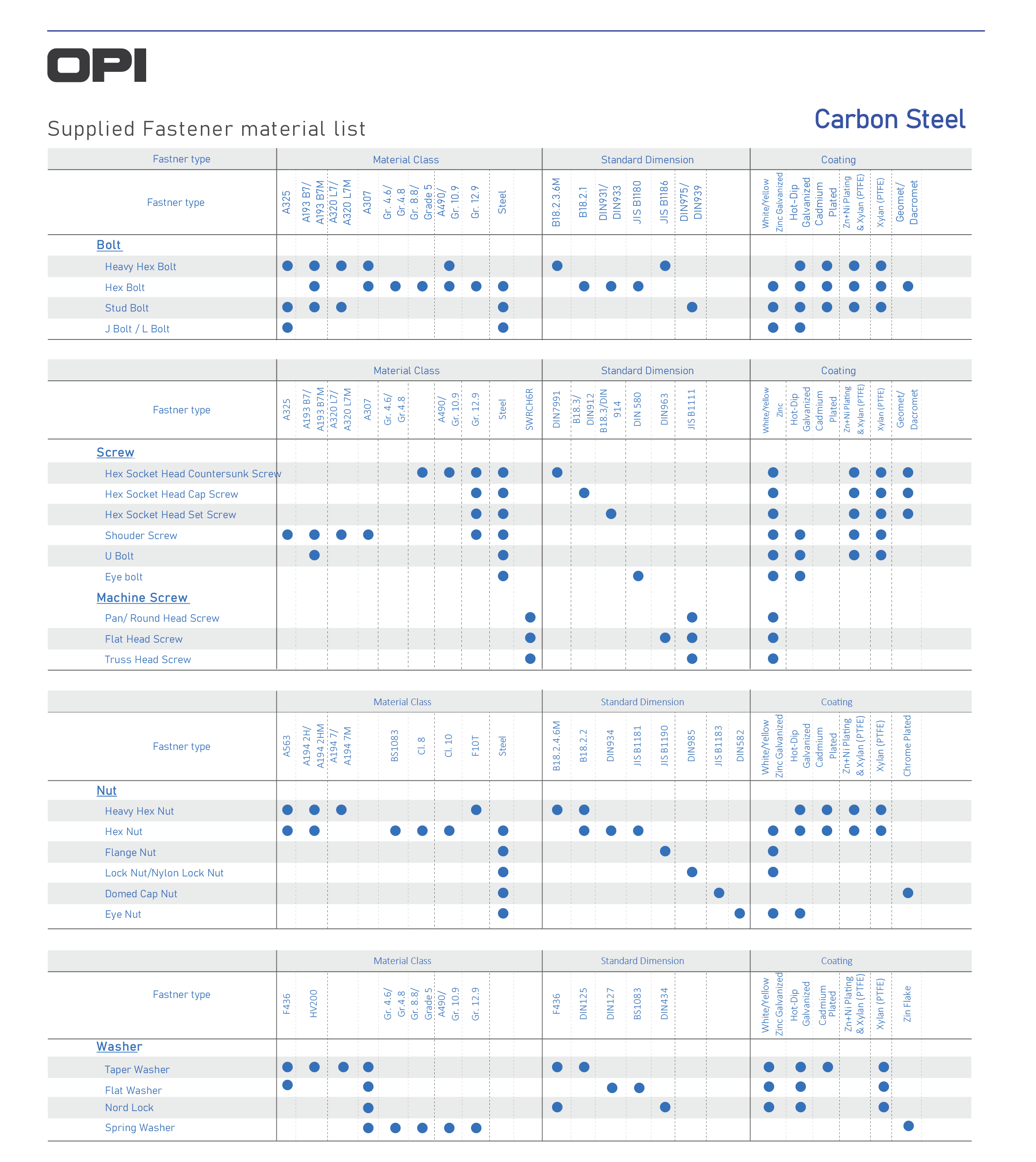

Supplied Fastener material list

We offer a wide-range of regular

and custom-made fasteners

made to internationally-upheld

safety and quality standards

for various project worldwide.

FASTENER COATING

Cadmium offers excellent corrosion protection, particularly in

harsh environments such as marine or aerospace applications.

The cadmium layer provides good wear resistance,

contributing to the bolt’s longevity and performance.

In case of damage, cadmium can act as a sacrificial

coating, corroding in place of the base metal, thus

protecting it.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

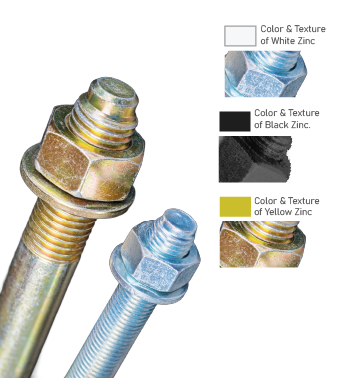

The zinc layer acts as a barrier, protecting the

underlying metal from corrosion caused by

exposure to moisture, air, and other environmental

elements.

Zinc plating is relatively cost-effectivecompared

to some other coating methods, making it a popular

choice for various applications.

Zinc plating can provide a n appealing finish and

can be further treated for improved aesthetics or

additional protection.

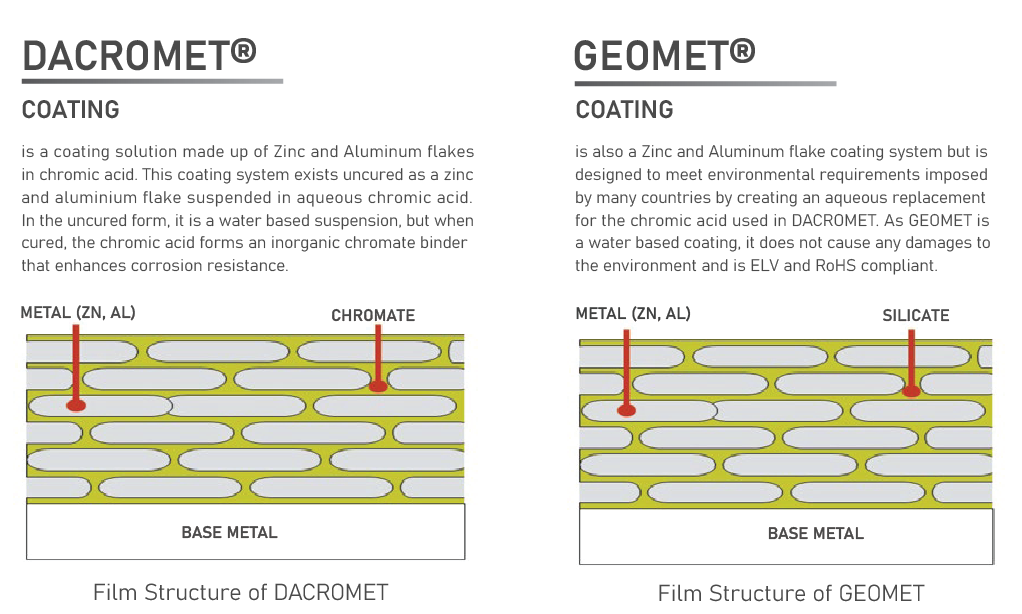

One layer ofDACROMET® and GEOMET® has demonstrated

0% red rust after 1000 hours of Salt Spray Test hours (tested

against ASTM B117).This performance exceeds that of Electro

– Galvanizing, Hot Dip Galvanizing and Mechanical Galvanizing.

The corrosion resistance capability can be further enhanced by

applying multiple layers of coating. Alternatively, DACROMET®

and GEOMET® can be trusted as a base coat to be applied with

other top coats. The inorganic base coat protects the substrate

from any chemical reactions and the overall corrosion resistance

will be increased exponentially.

“Hydrogen embrittlement may cause premature failure of parts which are heat

treated

or cold worked to a surface hardness of 320HV

and above or property

class 8.8 or above.” BS 7371-6

AT LEAST 1000 HOURS OF SALT SPRAY TEST

One layer of DACROMET® and GEOMET® has demonstrated 0% red rust after 1000 hours of Salt Spray Test hours (tested against ASTM B117).

This performance exceeds that of Electro-Galvanizing, Hot Dip Galvanizing and Mechanical Galvanizing.

The corrosion resistance capability can be further enhanced by applying multiple layers of coating. Alternatively, DACROMET® and GEOMET®

can be

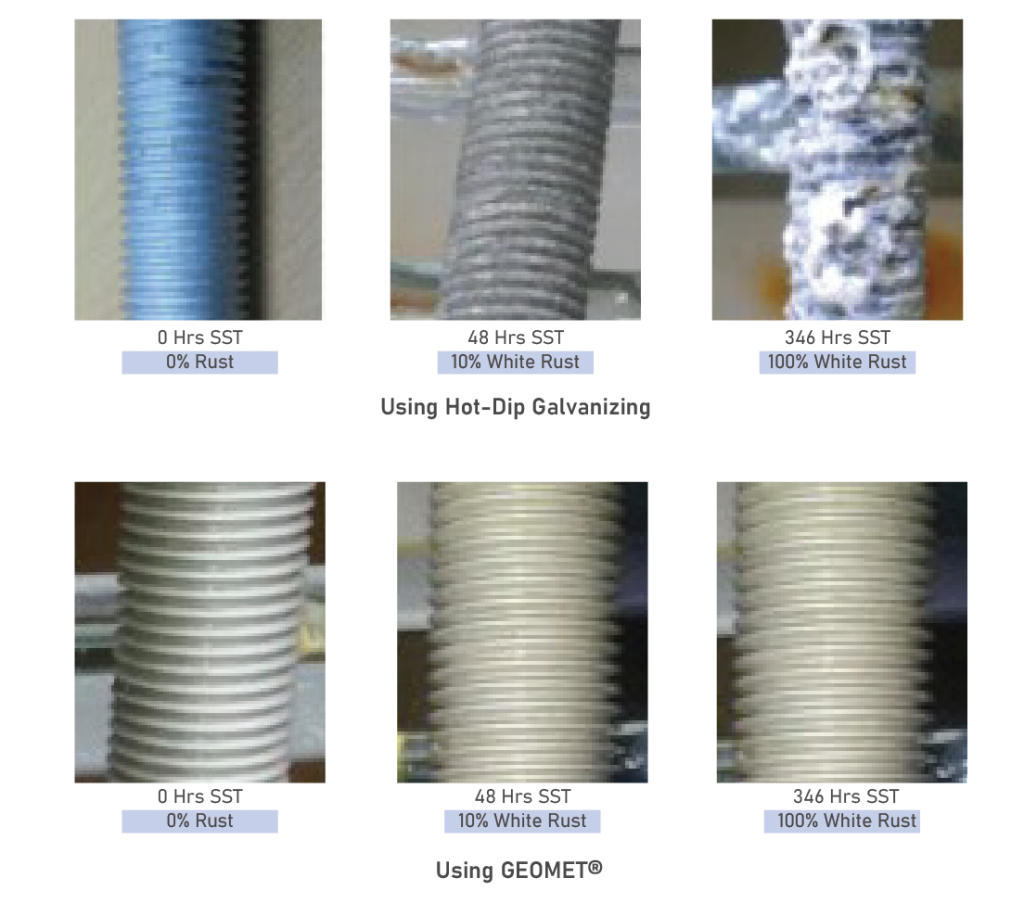

SUPERIOR ALTERNATIVE TO HDG, DACROMET® and GEOMET® coated fasteners have demonstrated superior corrosion resistance

performance compared to HDG ones. When we performed salt spray test as per ASTM B117 on both types of bolts, HDG bolts began

to have 10% white rust at approximately 48 hours whereas DACROMET® and GEOMET® coated bolts are still in exhibiting 0% white

rust and red rust after 1000 hours of salt spray test.

In addition, hot dipped galvanizing requires a minimum coating thickness of 36 microns. To compensate for the fit between bolts and

nuts, ASTM A153 allows the nuts or tapped holes to be tapped to meet over-tapping allowances. DACROMET® and GEOMET® do not

require any reworks as the average coating is only 8-10 microns.

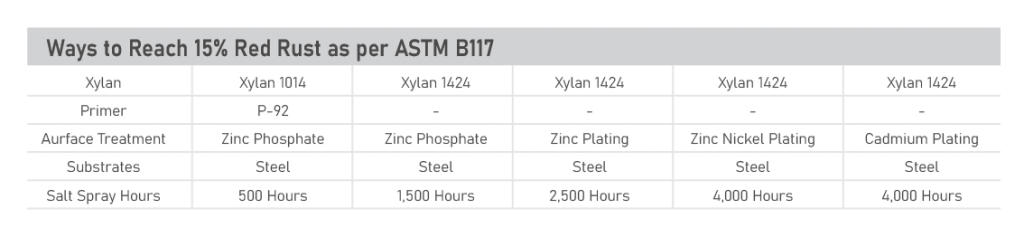

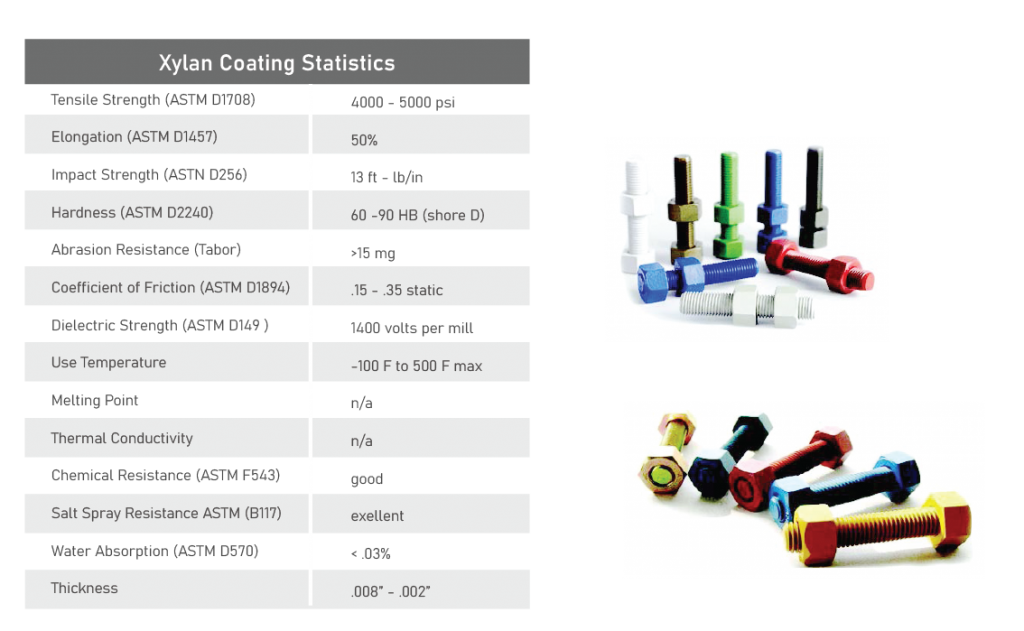

XYLAN COATING

Fluorocarbon coating : Superior Corrosion Resistance

Xylan coating provides outstanding protection against

corrosion in various environments. This fluoropolyme

-based coating shields bolts and nuts from moisture,

chemicals, and corrosive elements, ensuring prolonged

durability even in harsh conditions.

Meterials that coated with Xylan coating are often considered suitable

for use in petrochemical applications. The Xylan coating offers several

advantageous properties that are beneficial in such environments:

TUNNEL SYSTEM

TUNNEL SEGMENT ACCESSORIES &

RAIL / TRACK FASTENING SYSTEM

Since the construction of the first MRT line in Singapore in the 1980s, we have manufactured and supplied accessories for the tunnel & rail projects. Our rail fastening systems, tunnel segment lifting systems and tunnel segment linking systems are used in various tunnel & rail projects throughout Southeast Asia.

STEEL DIVISION WORKS

With our partner